Introduction

The Colnago C40 was NOT the first carbon frame designed by Colnago, but following it’s release in 1994, the C40 was ridden to victory in some of cycling’s biggest races. Most notably 5 wins in Paris Roubaix – over the roughest parcours found in professional racing.

Colnago designed a number of carbon fibre bikes before the well known C40. These early bikes include;

- Colnago Carbon Olympic TT Road Bike (1984)

- Colnago Concept (1986)

- Colnago Volo (1988)

- Colnago C35 (1989)

- Colnago Carbitubo (1989)

Please read my article on Colnago’s First Carbon Fibre Bikes to learn more about these models and what was happening in the industry at the time.

Colnago C40 Prototype (pre-1994)

When researching the C40 on the internet, there is mention of an earlier carbon lugged frame with round carbon tubes rather than the Master profile tubes usually found on the C40. However, I decided to only include C40 frames in this article that were listed in the Colnago catalogs and were therefore widely available to the general public.

Colnago C40 (1994)

The C40 name originates from ‘C’ for Carbon and ’40’ in recognition of Colnago’s 40th anniversary (1954 to 1994). It was in production for approximately 10 years (1994 – 2004) and eventually superseded by the Colnago C50. Over the 10 years, the frame was revised on 3 occasions – so there are 4 different versions of the C40 frame.

The Colnago C40 proved to the cycling industry and consumers that carbon frames were not only light and stiff, but extremely durable. It’s now 27 years since the release of the C40 and carbon fibre is still the material of choice for high performance bike frames. In 1997, the C40 frame apparently cost GBP 1650.00.

In an interview with Ernesto Colnago, the C40 was listed as one of his most favorite bikes. Sir Bradley Wiggins was also quoted as saying the C40 is probably his most favorite bike to look at (having not ridden it yet – he bought a frame on eBay for his collection). With it’s classic lines, racing pedigree and history, it’s easy to see why any serious cycling enthusiast (myself included) would like to own a C40.

For many years, the C40 was also sold with a steel Precisa fork of which there are 2 versions. It wasn’t until late 90’s to early 2000’s when the C40 was sold with a carbon fork (Star or Force models). Detailed information about the different frames and forks is discussed later in this article.

Image courtesy of Steel Vintage Bikes

Clever Design of the C40: Carbon Lugs.

Whilst the C35 was built as a monocoque frame design (just like modern carbon road bikes), the C40 was built using carbon lugs, which saved weight and could be bonded to the carbon fibre tubes to create a single homogenous structure. Colnago was able to achieve this by taking advantage of Ferrari’s technology derived from exploring new ways to work with composites and join structural members as part of the development of the Ferrari F40 super car.

This carbon lug frame building technique has been used for every ‘C’ series bike since the C40 ie. C50, C59, C60 and the current C64 model. By manufacturing the lugs in 19 different angles, Colnago was able to manufacture frames in many different sizes or with custom geometry – just like they were doing for so many years with their steel road bikes. The image below highlights the variety of lug angles.

Whilst the frame tubes and 4 x lugs were constructed from carbon fibre, alloy parts were still used to complete the frame such as the threaded bottom bracket insert, cable stops, cable guides and the rear drop-outs which were bonded to the seat stays and chain stays. Regardless, when the C40 was released in 1994, it was lighter than any other frame on the market. An Art Decor painted 54 kg frame weighed just over 1 kg (excluding the steel Precisa fork).

Colnago C40 Major Race Wins

The C40 was extremely successful, winning nearly 1000 professional races in 10 years. Paris Roubaix is well known to be the toughest race on both equipment and rider with it’s many rough cobbled sectors which are essentially back roads used by farm vehicles throughout the year. Here’s an interesting story regarding the C40 prior to it’s first race in Paris Roubaix.

When we built the C40 we were the only ones to build carbon frames and all the mechanics and competitor technicians were saying that they would be too dangerous to use on cobbled roads, especially with the straight carbon forks. There was a company that wanted to fit suspension forks on the bicycle, but I wasn’t going to have suspension forks on the C40. The night before Paris- Roubaix I had Mr. Squinzi, the Mapei boss, on the phone to me raising his concerns about using such a delicate-looking thing. I told him that we’d done all of the tests that we could on the frame and the fork and we were certain there would be no problem. I had to take personal responsibility for what was going to happen and I spent all night worrying about it, barely able to sleep. But when I heard that there were 4 Mapei riders in the break, I knew I could relax.

Wikipedia on Colnago

The C40 was ridden to victory 5 times in Paris Roubaix; Franco Ballerini (1995 and 1998), Johan Museeuw (1996 and 2000) and Andrea Tafi (1999).

It was also ridden to victory in 3 World Championships (Johan Museeuw 1996, Oscar Camenzind 1998, Oscar Freire 2001) and the Giro d’Italia (Pavel Tonkov 1996).

4 Different Versions of the C40 Frame

Over the 10 year production period, 4 different variations of the frame were released (dates are approximate).

Please click on each version to learn more.. (coming soon..)

- First Version; the original design (1994-1996).

- Second Version; with revised down tube & chain stays, relocated shift cable stops (1997).

- Third Version; with revised seat stays. The C40 B-Stay (2001).

- Final Version; with revised chain stays. The C40 B-Stay HP (2003).

Notes:

1. According to this forum, the bottom bracket insert was changed from aluminium to titanium on C40 B-Stay models in 2003, just before the release of the C40 B-Stay HP. However, in a different article by Lennard Zinn, this change occured in the 2002 C40 B-Stay frames.

2. According to this forum, the shape of the seat/top tube lug on the C40 B-Stay was altered around 2003 and a replaceable derailleur hanger was added to the frame. These changes most likely coincided with upcoming release of the C40 B-Stay HP, but I found no mention of these upgrades in the Colnago catalogs.

5 Different Versions of the Fork Supplied with the C40

Over the 10 year production period, 5 different variations of the fork were released (dates are approximate). Please click on a particular version to learn more.

- Original steel Colnago Precisa fork (1994)

- Revised steel Colnago Precisa fork (1995)

- Time ‘Colnago’ Carbon fork. Not mentioned in any of the Colnago catalogs I have. This fork was offered whilst Colnago was developing their own carbon forks. Time are a French bicycle company founded in 1987.

- Colnago Star Carbon fork (late 1990’s, appears in 2000 Colnago catalog).

- Colnago Force Carbon fork (late 1990’s, appears in 2000 Colnago catalog).

Note: Both the Force and Star fork steerer tubes were originally manufactured in 1″ diameter to suit all versions of the C40, but later manufactured in 1-1/8″ diameter to suit the C50 frames.

Colnago C40 Frame Specifications

I believe all versions of the Colango C40 had the following frame specifications;

- Seat post diameter: 28 mm (not a common size).

- Bottom bracket: Italian threaded, width 70mm.

- Headset (early models): 1 inch threaded.

- Headset (later models): I inch threadless (determined by the fork steerer tube) .

- Rear frame spacing: 130 mm.

- Front fork spacing: 100 mm.

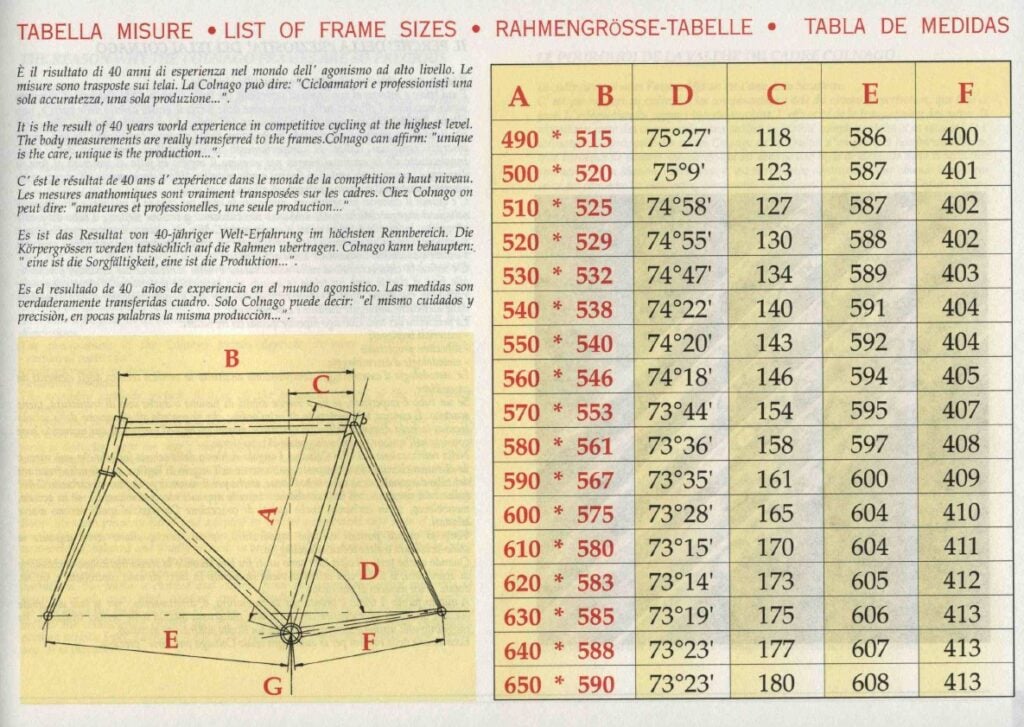

Colnago C40 Geometry Chart

This geometry chart was listed in a 1994 Colnago catalog when the C40 was released. Colnago frames of this era still featured traditional geometry with a straight (non-sloping) top tube design. However in 2001, their catalog listed sloping geometry for the small frames sizes (46,47,48) – not show in this table.

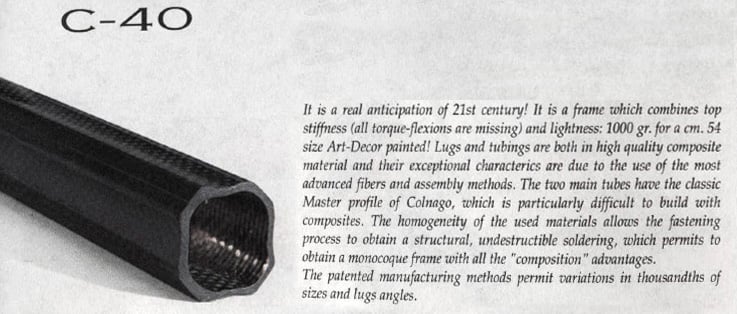

Carbon Tubes used to build the C40 frame.

Apparently all the carbon tubes and lugs were manufactured by ATR srl. a high-tech Italian company specializing in carbon fibre fabrication, whom were also suppliers for Ferrari. These parts were then shipped to Colnago where the frame was assembled in their factory. More on that process later in this article. The carbon tubes were refined over the 10 year manufacturing span of the C40 to make them stiffer and lighter. Both the top and down tubes feature the Master profile as seen in the image below.

It is a real anticipation of 21st century! It is a frame which combines top stiffness (all torque-flexions are missing) and lightness: 1000 gr. for a cm. 54 size Art-Decor painted! Lugs and tubings are both in high quality composite material and their exceptional characteristics are due to the use of the most advanced fibres and assembly methods. The two main tubes have the classic Master profile of Colnago, which is particularly difficult to build with composites. The homogeneity of the used materials allows the fastening process to obtain a structural, undestructible soldering, which permits to obtain a monocoque frame with all the “composition” advantages. The patented manufacturing methods permit variations in thousandths of sizes and lugs angles.

Extract from 1994 Colnago Catalog

C40 Frame Assembly Process

Rather than simply cut the carbon tubes straight and fit them into the lugs, Colnago precisely miter each carbon tube to ensure the end of the tube perfectly mates with the internal surface of the lug, with no gaps, to achieve maximum strength. Once the frame tubes are cut to the required lengths, the ends are coated in a special bonding agent before being inserted into the carbon lugs. The assembled frame is positioned on a special jig to ensure everything is set in perfect position.

The following images from a 1997 Colnago catalog show the assembly process of a C40 frame.

Galvanic Corrosion in early C40 frames

We all know that one of the benefits of carbon fibre is that it doesn’t rust. Unfortunately though, it can accelerate corrosion in metal parts that are connected to it. This is a known as galvanic corrosion.

Search around the web and you’ll find plenty of discussion related to C40 frames experiencing galvanic corrosion. Carbon fibre is an electrically conductive material and when coupled to fittings comprised of untreated aluminium alloys, these fittings become susceptible to galvanic corrosion.

In the case of a bicycle frame, when a large surface area of carbon composite is coupled to small metallic parts (such as cable guides, cable stops and rear drop-outs), the rate of galvanic corrosion is extremely high due to the high cathode to anode surface area ratio (Ac/Aa).

As I understand, this issue was resolved in later versions of the C40 frame by treating the alloy parts. Titanium bottom bracket sleeves were also used in late model C40 frames.

The areas susceptible to corrosion on the early C40 frames were;

- The alloy rear drop-outs. They are bonded to the seat stays and chain stays in the rear triangle.

- The internal aluminium bottom bracket sleeve.

- The alloy cable routing guides and stops.

The best ways to prevent corrosion are;

- Make sure the paintwork on all metal parts is in good condition to provide a barrier to the elements.

- Store the bike in a dry location (away from salt air if you live close to the ocean).

- Avoid riding in wet weather where salt is present on the road.

- Wash and dry the bike after riding in the rain.

- Wipe off any perspiration after a ride.

References

I hope you found this article interesting. I have listed the following website pages as general references.

- Colnago C40 Background

- C40 – One of Ernesto’s favourite bikes

- C40 – Major Victories

- Road bikes with front suspension forks – 2 wins in Paris Roubaix

- Bradley Wiggins – C40 one of his most favorite bikes

- C40 – Updates over the years

- C40 – Manufacturing process

- Galvanic corrosion caused by carbon fibre

- Colnago tech bulletin – discussing carbon fibre

- Durability of carbon fibre forks and frames

About Me.

I have been riding and working on my own bikes for many years now. I wanted to share my experiences, knowledge and research with others. My aim is to inspire people to get involved in all aspects of this amazing sport. Cheers.

Comments.

I welcome reader feedback in the comments section. Should you wish to suggest an amendment, please include a note advising the source of your information so that myself and other readers can ascertain the accuracy of your information. Note: Trolling or argumentative comments will be removed as they are counter-productive.

Hello,

I was looking at a Dream Art Decor frame on ebay. I noticed the work aluminum was spelled Alluminium on the frame. Does that sound right to you? It’s a frame and fork only. It has a headset for a quill stem and an octalink BB in it so I think that dates it to the mid 90s

Hi Lee, sorry I haven’t spent any time researching the Colnago Dream, but I believe they were released in the early 2000’s.

Hello, and thank you for this great info! I just purchased a used C40 and was hoping to positively identify it, as I’m considering replacing some of the parts that are currently mounted to the frame. Is it possible to:

– Upgrade the drivetrain to 11-speed?

– Upgrade the stem and/or handlebars to something a little more modern?

Looking forward to your insight.

Hi Brandon, whilst I haven’t done this personally, I believe it is possible to fit modern components to a C40 frame.

(a) The spacing of the C40 frame drop-outs is 100 mm (front) and 130 mm (rear) which is the same as any modern RIM BRAKE road bike. You can fit any mechanical group set built for rim brakes (even 12 speed). Fitting a modern group set may require you to fit a new rear wheel so the freehub body is compatible with the cassette. You can fit any standard alloy or carbon wheels (for rim brakes) on the C40.

(b) You will need an Italian threaded bottom bracket designed specifically for the group set you are intending to fit eg. SRAM, Shimano or Campagnolo.

(c) Your fork steerer tube will either be 1 inch threaded or 1 inch threadless with a matching headset installed.

This 1 inch diameter steerer tube is an old standard. Modern steerer tubes are typically 1-1/8 inch diameter and use modern threadless headsets & stems. Luckily there are a wide variety of shims, adapters, converters available to convert an old 1 inch diameter fork steerer to a modern 1-1/8 inch diameter. Some of these options may require you to fit a threadless headset, others will work with an original threaded headset. Some of these options give you extra height to fit spacers under the stem, particularly useful if the original steerer tube was cut quite low. Once this conversion is done, you can fit modern stems and handle bars. Before you start you need to determine if you currently have a threaded steerer & headset or a threadless setup.

(d)

When using quick release skewers on steel frames with horizontal dropouts, I recommend that the knurled teeth of the skewer ie. the ends that grip the frame drop-outs are made of STEEL. This will ensure they are strong and durable enough to grip the steel dropouts. The outer parts of the skewer can be aluminium, but these inner pieces need to be steel. Use a magnet to test. This is particularly important for the rear wheel which requires the quick release to be done up more tightly than modern frames with vertical dropouts. If the rear QR is not tight, the torque generated at the cranks can pull the rear wheel out of alignment and the tyre will rub on the inside left chain stay.*Amendment* Colnago C40 features alloy drop-outs so any normal wheel skewers can be used.Removing & installing a headset, bottom bracket etc. can require specific tools. If you don’t have these tools, a bike shop would be best to assist with this process. Once you have done it, please post a comment on how it went and how good the bike is to ride with a modern setup!

Here are some ideas;

CyclingTips article

ProBikeKit convertor

Bike24 Shim

Appreciate the insight!

It appears the previous owner may have done some of this work in the cockpit. The stem and handlebars are a more modern ITM carbon monocoque, but are still old by today’s standards. The headset, however, is a Chris King “NoThread” threadless headset, and it does look like there’s an adapter or shim in place already… though I’ll have to disassemble it to be sure what’s all there. I’m headed to a local shop who has agreed to assist next week so I can get the cockpit sorted with something newer and not as wide as 450 mm.

The drivetrain will be a longer process of course, but I’ll know after my bike shop visit what’s possible there. The current 10-speed Dura-Ace setup is older, yes, but still smooth as silk and fun to operate. The desire to upgrade to 11-speed is mostly driven by my desire to use the newer and fantastic HED wheels I have on hand, which are orders of magnitude lighter than the Mavic wheels currently mounted on the C40. I would love to use these wheels, but their hub is an 11-speed Shimano hub, and the current setup obviously wouldn’t work with it. The drivetrain upgrade would allow me to use these wheels, and I think my riding fun would multiply significantly.

I will post here as the journey unfolds! It’s such a neat frame with a fascinating history, so I’m excited to keep it on the road. It definitely gets the looks.

Thanks again!

I believe you can run your old Shimano 10 speed group on modern wheels with a Shimano 11 speed freehub, so you don’t need a group set upgrade. You just need a small spacer fitted on the freehub behind the largest cog. This spacer was sometimes supplied with an 11 speed wheelset in a bag of parts. Your bike shop should know. Image of a cassette spacer

I also just added one more point (d) to my original comments in relation to quick release skewers.

Hi. Great web page. Love it.

I’m unsure why are fairly vocal about steel skewers. I’ve ridden C40’s since 2,000 including racing in all conditions. I used to put out +1,300W in sprints. I ride mostly very light weight skewers, and only steel skewers on a few commuter type wheels where I most certainly don’t go anywhere North of 400w. I have never had a wheel slip in the dropouts. I’ve never even lost a wheel in a crash despite destroying the frame completely. I’m just curious what you base your recommendation on, which in other areas appear faultless. Regards.

Hi Anders, thanks for your comments, over 1300W sprint is impressive. You are correct, the C40 does not require steel skewers, normal skewers are just fine to use. When posting that comment, I forgot the C40 actually has alloy drop-outs bonded to the carbon tubes, not steel drop-outs, like all the other Colnago steel frames discussed on my website. Because alloy is much softer than steel, regular skewers can grip the rear drop-outs just fine. My original comments regarding the requirement for steel skewers only apply to steel drop-outs found on steel frames. I have amended the original comment.

Greetings,

Great post, BTW. Very informative. I’ve been riding a Master for the last 16 years, and she’s getting bit long in the tooth.

I always admired the geometry and paint job on the C40, so for the last couple of weeks I’ve been combing the Internet looking for used in excellent condition, or NOS. I’ve found a NOS in 55cm, which is a tad short from the 57cm that I have been riding for the last 40 years. But, I’m getting older, and maybe a slightly smaller frame might not be so bad? I could always get a 110 stem instead of the usual 100 that I’ve been using. Thoughts?

One thing I noticed in your discussion was that you said all C40’s were made with Italian BB’s. The C40 that I have found that is NOS, and current production Master’s are offered as either Italian or English threads. The C40 that I’m eying is English thread. FYI. My Master, which is from 2005 is Italian.

Cheers, Jared Purdy

Hi Jared, thanks for your comments. A NOS C40 frame sounds fantastic. I would expect they are definitely hard to come by, but correct fit is SUPER IMPORTANT if you want to ride it.

The first thing you need to be sure about is how is the frame measured? Is the 55cm frame size measured centre to centre (C-C) for the seat tube? I have a Colnago Nuovo Mexico which measures 55cm C-C on the seat tube, but in Colnago’s size chart for steel frames, this is a 57cm frame; measured centre to top (C-T) of the seat tube. Looking at the C40 size chart in my article, it appears Colnago measure C-T for the C40 frames also. Make sure you have detailed measurements to compare both frames. If you are considering changing to a frame with a seat tube 2cm shorter than your current bike, the following needs to be considered;

Moving to the smaller frame will likely reduce both frame stack and reach. You already mentioned the reach difference that will require a longer stem, but the smaller frame also has a reduced frame stack; which will change your saddle to handle bar drop. This is because the seat tube on the smaller frame is shorter and so you will need make up the difference by having more exposed seat post in order to position your saddle at the correct height. Increasing saddle to handle bar drop puts you in a more aggressive (aero) position as the handle bars are now lower. Pro riders sometimes ride smaller frames with longer stems to get a more aero position.

In order to cancel out this increased saddle to handle bar drop, you need to raise the handle bars which may be achieved using a taller (quill) stem or fitting a modern stem with more spacers / or riser stem. This needs to be carefully considered in relation to the height of the stem on your existing bike. It may be difficult to achieve your normal handle bar height. I don’t recommend fitting more than 30mm of spacers under a modern stem.

Finally, if the seat tube angle of both frames is the same or very similar, you shouldn’t need to adjust your saddle fore/aft position much as the combined length of the seat tube & seat post will be the same for both frames regardless of the frame size. However, if the seat post angles are different, then the saddle will need to be repositioned fore/aft.

I would suggest visiting a knowledgeable bike fitter with your current bike to discuss the possibility of transferring your riding position to a smaller frame.

In terms of BB threading, I assumed the C40’s were all Italian threaded from the few I had seen, but interesting to hear you have found one with English threading. Nearly all modern frames have English threading, it became the standard for good reason. Pinarello still use Italian threading on the Dogma as a noticeable exception. What year/version is the NOS C40 frame you are looking to buy? Please post a link to this frame in the comments, I would love to see it. Best of luck.

All C40’s have Italian threaded BB’s. Both the English and Italian BB’s have 24tpi threads however the shell width of the BB will be 70mm whereas an English BB is 68mm. I own Mk2, 3 & 4 C40’s, all Italian and so are my two Masters.

Thanks Andrew for confirmation of an Italian BB on the C40.

Hi,

I just buy a C40 1st generation (I think m) but I have a different fork. I can’t post a photo here but I find an announce with the same as mine (I think).

https://buycycle.com/fr/bike/c40-51641896374

Do you have an idea about the fork?

Hi Olivier, looking at the picture, I believe that fork is a painted Colnago Precisa steel fork which is discussed in the article.

This is one of the very original C40’s which has a non precisa fork. Very rare.

Hi Andrew, thanks for pointing that out, on closer inspection of the photos, the fork crown is a different design to the standard Colnago Precisa versions.

Hi Rouler,

I am regretting buying a 2nd version C40. First prob was a cracked, at very top 40cm, steer tube. Seller gave me a replacement Time fork. All well and good.

NOW I have a loose bottle mount. These are 5mm internal threads correct? My tap seems to bottom out after only a few mm. And how can I repair the loose mount? It does not lift out, it just spins! Thanks,

-Robin ; (

Hi Robin, sounds like you have had some bad luck with that frame. It should be possible to get a bottle mount repaired by a carbon fibre specialist. Ask at your local bike shops or search online for a repairer. Some automotive repairers can do carbon fibre repairs as well if you get desperate.

Yes, blaming myself more than the frame. I ordered a blunt or “plug tap” which has fewer starter threads to chase the rivnuts. There is def a narrower “neck” that I can see inside these “rivnuts.” I used some epoxy under the loose rivnut, maybe enough to chase the threads and get shorter fasteners. Thanks! There is a carbon repair guy close to me.

-Robin

Interesting article/page you have put together, well done.. I have a c40 which I bought in 1999, it has a Time fork..!! In the Colnago brochure for 1999 there is a foto of three c40 frames, two of them have the steel precisa forks, the middle one has a Time fork, and the caption reads – ND10 + Time vork…

Definitely a bike of legend, what a history. I love Colnago’s story about how he didn’t sleep the night before the first c40 win in Paris-Roubaix!!!

The first c40s were released in 1994 but there were pre-production prototypes ‘seen’ in 1993. They were not labelled as c40s…!!! Tony Rominger had a version while winning 1993 Vuelta, I think the rear dropouts were different, but the carbon lugs and tubes were c40 style…!!!

I have a “purple” c40 art decor a-stay. Ex racing bike, but not a team bike. I believe it was in TDF 97 or 98 as a spares bike for teams to use like the yellow mavic bikes now. It has no serial number. Do you have any information on them? I believe there are only 6. One in each size. It’s a race bike as the Colnago lettering on the fork is front visible. It was the original showcase bike for Campagnolo Ergo 9 shifters. And yes it’s Purple, not blue.

Love the work you’ve put in for presenting this!

Feel free to have a look at my 1999 Colnago C40 in 00F colour scheme:

https://www.pedalroom.com/bike/colnago-c40-mkii-1999-42059

Good morning, thanks for the great articles and insight. I recently bought a C40 off E-bay from a reputable seller. Doesn’t have the original fork and seems to have been resprayed at some point. Seller advised that he bought it as is so I’m curious to know what I’ve actually bought and hoping that I have not been taken for a ride🤦♂️

i am surprised you havent included a link to this long-time C40 reference, available freely on the internet: http://brown-snout.com/cycling/tech/_colnago-c40-family-tree.pdf

Hi Wallymann,

Yes, I have seen that page before, it is a good summary of the models that prior to, including and after the C40.

My area of interest was purely the C40 with my pages discussing variants with images, so I decided there was no need to reference that post.

However, the link is now provided in your comment should anyone want to visit it, they can.

Hi there

I have a Colnago C40 that I’d like to sell. Any idea what it’s worth?

There are a lot of factors that will affect the value of a bike, but if you sell at auction on eBay, you should get a price the market is willing to offer.

I’m finishing the restoration of a 2nd generation C40 that was poorly treated by the prior owner. Many of the parts were “updated” over the years and I’ve been researching period correct replacement components (mostly 9-speed era Campy Record parts). I’m baffled about the handlebars. I’ve found a Colnago panto stem from ITM, and I’m guessing that ITM bars would be appropriate, but I’m not sure which model would be correct for 1997-98(ish). Sadly, there seems to be no historical information available for ITM at sites like velobase.

Sounds like a great project, I don’t have any old catalogues for ITM 1990s parts, but this C40 had ITM Super Italia Pro-2 bars fitted.